Multiple Properties, Multiple Benefits.

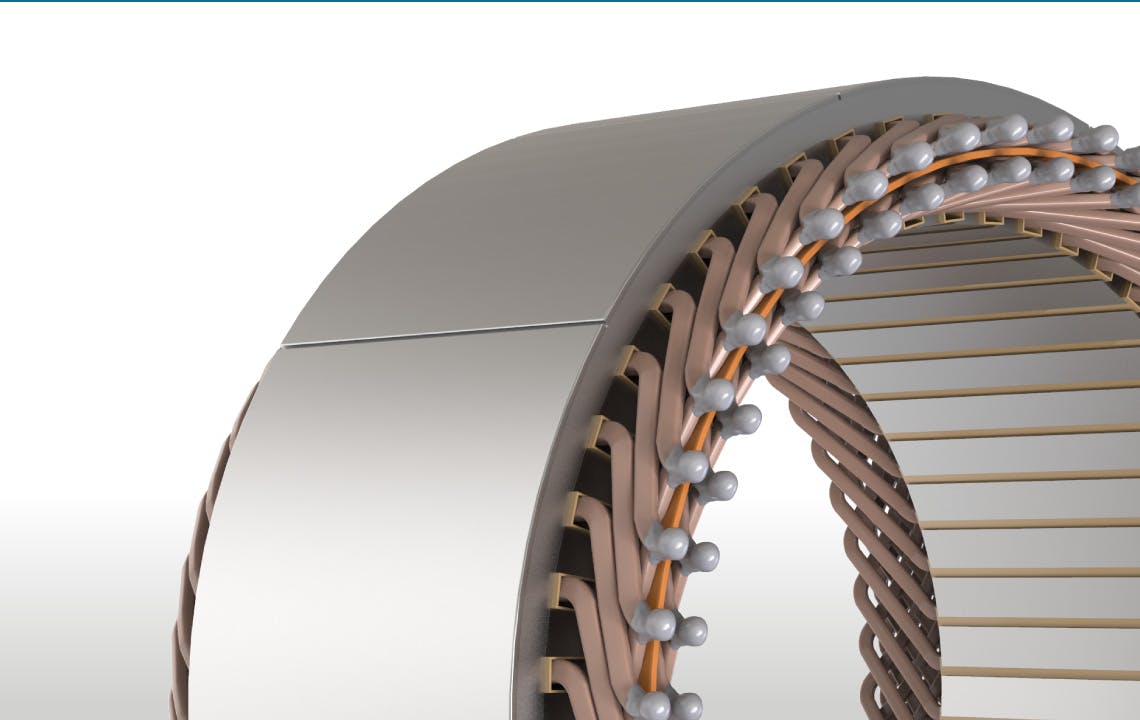

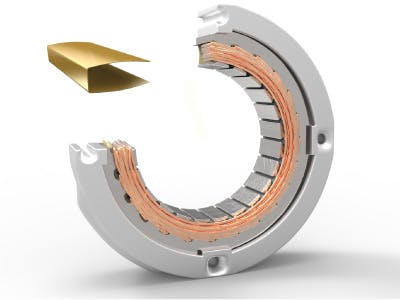

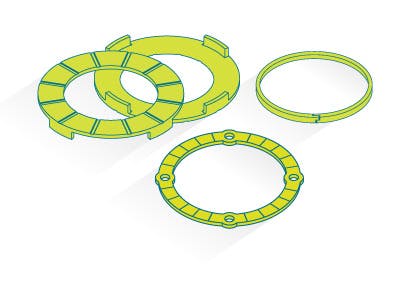

What kind of materials do you typically choose when your application faces multiple, complex requirements such as heat, electricity, chemicals, wear, stress... etc.? Such environment is where VICTREX PEEK polymers thrive, in many cases replacing metal - with proven track record in demanding applications such as braking systems, engines, transmissions and steering - making Victrex polymers, forms and parts the material of choice for countless customers around the world. PEEK polymer’s multi-faceted material performance addresses issues such as light-weighting, durability, efficiency and thermal management - check out how we may help you what's possible with your application development.

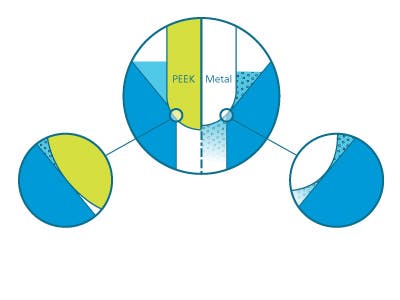

4x better PV values

In friction environments VICTREX PEEK has shown 4x better PV values than typically gained with standard polymer specimens, enabling reduced energy loss.

Stable Fluid Management

Learn about the benefits of VICTREX PEEK in demanding hydraulic applications.