VICTREXTM PEEK bearing solutions can enable wind turbines to produce more power and less downtime through improved reliability.

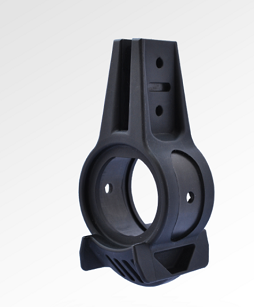

Replacing metal friction components with VICTREXTM PEEK Polymers enables

From Victrex medical division, Invibio's PEEK-OPTIMATM polymers for implantable devices address the increasing need for joint replacement and enhanced clinical benefits in the ageing global population. Application areas include dental, spine, trauma, knees, and others.

Replacing metal aero parts with thermoplastic composites enables

Applying APTIVTM PEEK film in mobile device acoustics enables

Applications made of VICTREXTM PEEK polymers keeps your equipment working overtime in the most critical environments

Hi, do you have PEEK questions I can help with?