VICTREX PEEK polymers, a potential PFAS replacement

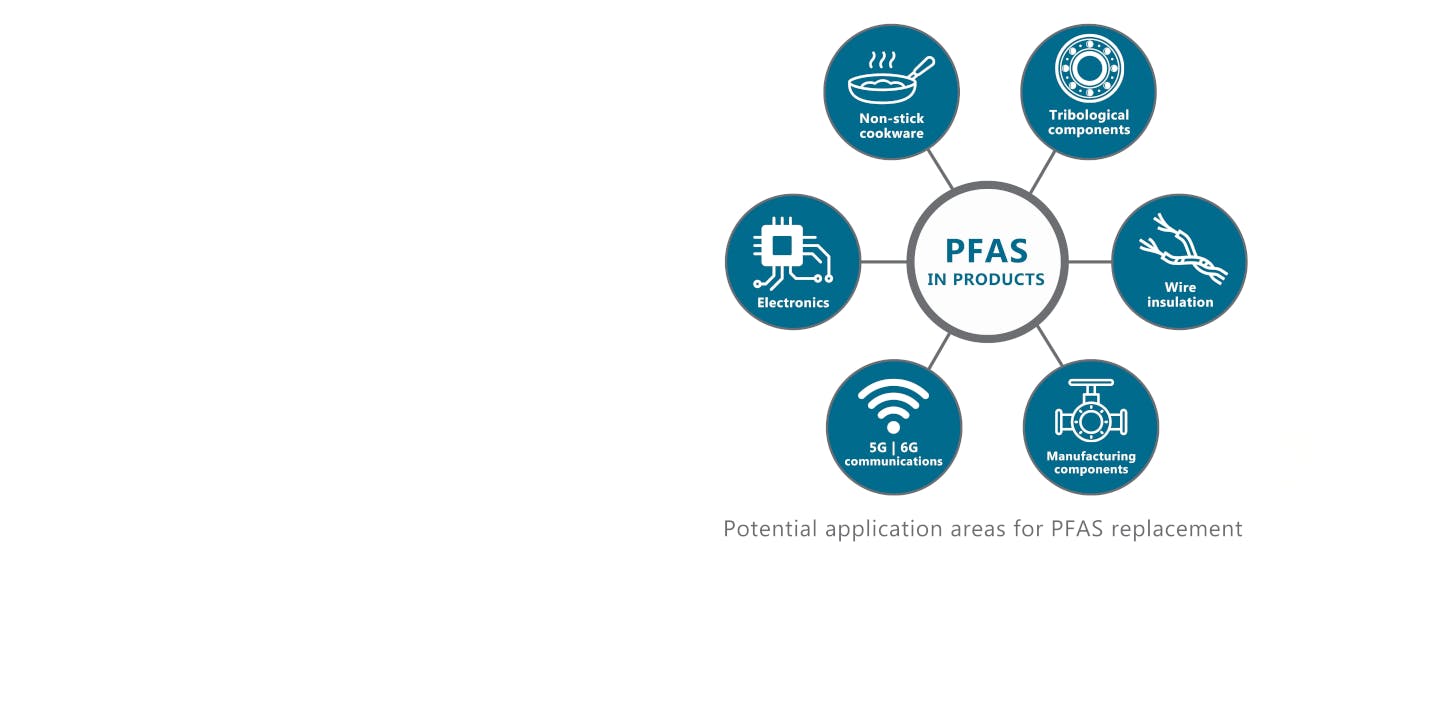

In the face of the PFAS concerns, we take pride in offering a range of proven high-performance PEEK polymers as potential safer and more sustainable alternatives.

PEEK polymers, regarded as one of the highest performing polymers in the world, are well suited for extreme and demanding environments and can support multiple requirements at the same time.

High temperature performance

Suitable for continuous-use temperatures up to 260°C (500°F). Glass transition temperatures up to 170°C (338°F)

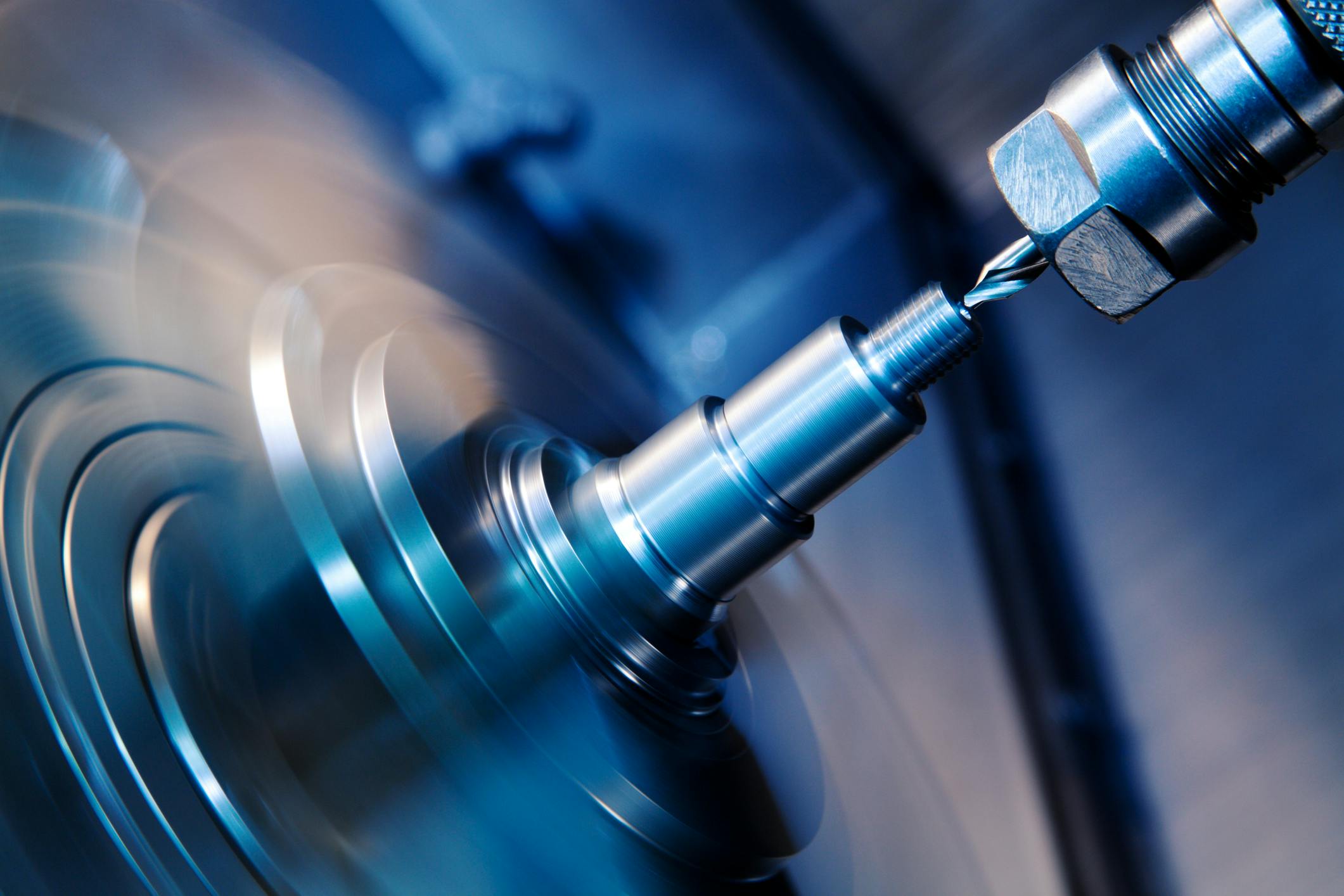

High wear resistance

Low coefficient of friction. High abrasion and cut-through resistance

Mechanical strength and dimensional stability

High strength and stiffness in demanding conditions. Excellent long-term creep and fatigue properties

Resistance to harsh chemicals

Withstands a wide range of acids and bases and shows excellent performance in hydrocarbons and organic solvents

Compliance

Meets applicable regulatory requirements and safety standards in its intended applications