온라인 세미나

Additive Manufacturing Podcast with DiLabs

Robert McKay, Head of business development and Silvia Berretta, Strategic technology manager of Victrex sat down with DiLabs to discuss VICTREX AM™ 200, a high performance LMPAEK™ filament.

온라인 세미나 보기

온라인 세미나

LMPAEK™ Polymers: The Foundation of Emerging Technologies in Aerospace

The potential solutions that LMPAEK™ materials can provide don’t just sit within structural parts or aircraft interiors. They also include structural thermal runaway protection, lightning strike protection, heat sinking applications, and complex bracketry. LMPAEK™ material-based solutions like unidirectional tapes, films and compounds are well positioned to address sustainability and future challenges. These material forms facilitate the use of automation and high-rate production techniques while doing so with low environmental impact, reduced weight and reduced system costs that transportation markets require.

온라인 세미나 보기

온라인 세미나

Advanced Thermal and Fire Protection for Aerospace and Automotive Applications With LMPAEK™ Unidirectional Tapes

온라인 세미나 보기

온라인 세미나

The Inside Story on Thermoplastic Composites for Aerospace Product Design

What are the benefits of #thermoplastics versus metallics or thermosets? How are allowables databases generated and used? What are key modelling approaches to composites and hybrids? Watch the webinar to find out.

온라인 세미나 보기

온라인 세미나

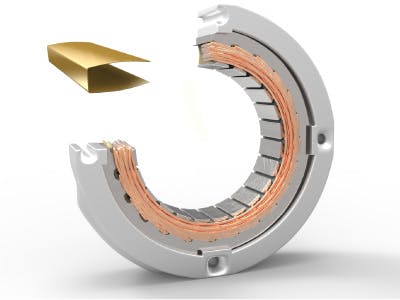

How new PEEK magnet wire coating with VICTREX XPI polymer can improve electric powertrain efficiency

To cope with higher voltage platforms and SiC switching technologies, requirements for e-motor insulation become more demanding. VICTREX XPI PEEK polymer coating can help improve e-motor efficiency (reliability, range and cost) vs enamel coatings.

온라인 세미나 보기

온라인 세미나

Sealed to Survive the Extremes

Learn why sealing components made with VICTREX PEEK are able to survive the most demanding conditions, replacing metals and other polymers.

온라인 세미나 보기

온라인 세미나

Thinner, Lighter, Smarter: Why Mobile Devices Need High-performance Polymers

Mobile devices made with VICTREX PAEK polymers can help your team reach new levels of performance with greater design freedom. Watch now

온라인 세미나 보기

온라인 세미나

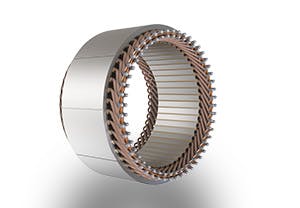

고전력 e-모터용 절연 솔루션 온라인 세미나

PEEK 기반 APTIV 필름의 인슐레이션 성능 및 혜택에 대한 보다 자세한 정보를 확인하실 수 있습니다.

온라인 세미나 보기

온라인 세미나

How to design innovative drug delivery devices with PEEK

Learn about the properties of PEEK that appeal to drug delivery device design engineers, such as chemical resistance and space-saving integrated electronics. During this webinar, two novel device concepts will be presented that demonstrate the potential of PEEK in connected devices.

온라인 세미나 보기

온라인 세미나

Assessing Polymer Performance in Hot and Sour Oil and Gas Environments

The webinar discusses the standard test methods for assessing high-performance polymers in hot and sour environments. This will help avoid some of the pitfalls which may lead to erroneous interpretations of the data generated.

온라인 세미나 보기

온라인 세미나

The Durability of PEEK Polymers in Thermoplastic Composite Pipes for Subsea Oil and Gas Applications

Learn about how VICTREX™ PEEK meets the demands of Oil & Gas transportation systems and hear about the qualification process, engineering, performance, risk and cost reduction opportunities when using Magma m-pipe®.

온라인 세미나 보기

온라인 세미나

Qualification of m-pipe® and Hybrid Flexible Pipe for deployment in Brazil’s pre-salt region composite material

The severe challenges of subsea operations in the ultra-deep water and highly corrosive Brazil pre-salt geological environments had been examined in the webinar co-hosted by Victrex and Smithers with guest presenters from TechnipFMC and Magma Global.

온라인 세미나 보기

온라인 세미나

Shaping Future Aerospace Performance with Thermoplastics

This presentation looks at PEEK thermoplastic resins, film, pipe, and materials for composites, and examines a case study involving collaborative efforts to develop next-generation clamping technologies for the Boeing 787.

온라인 세미나 보기