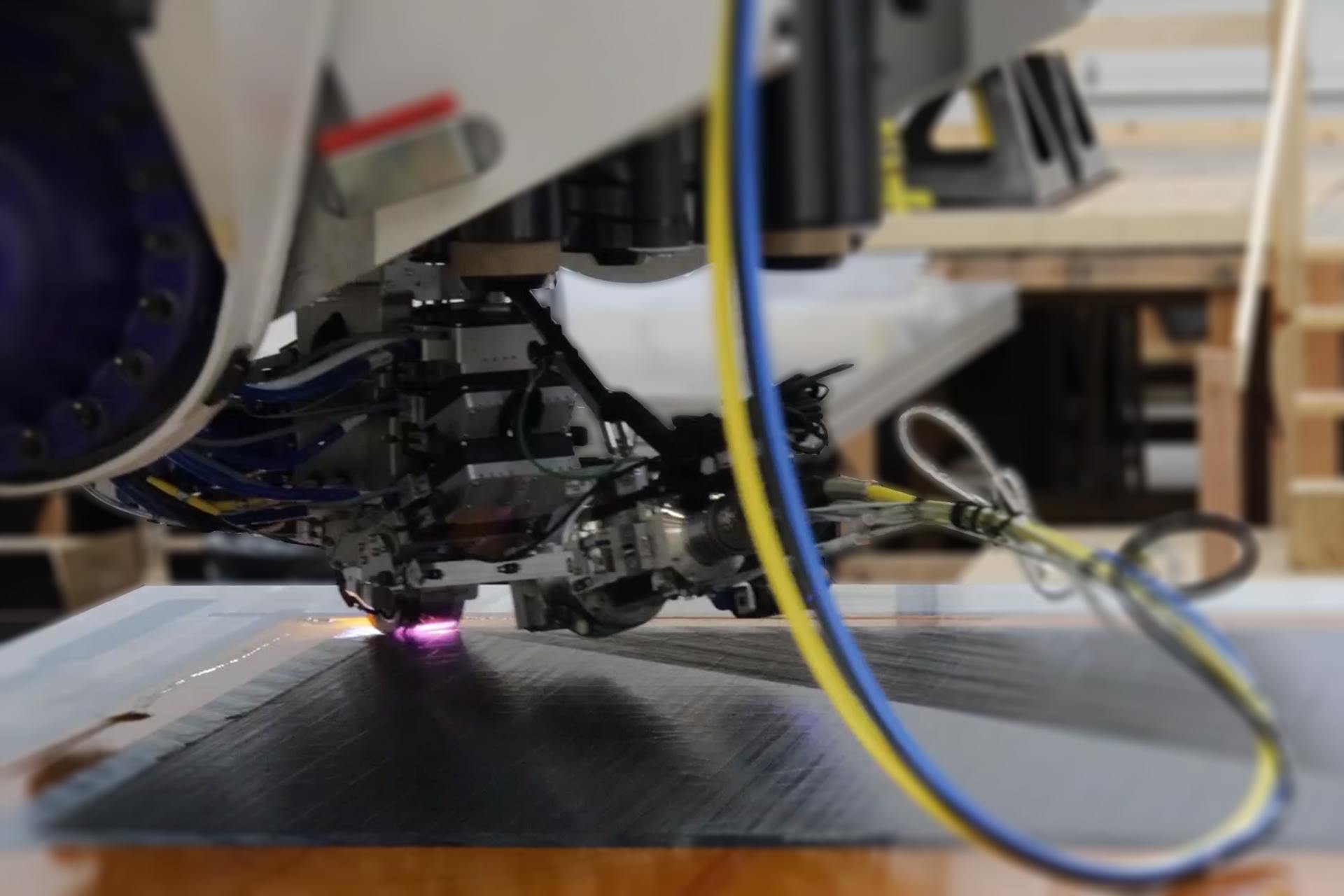

Coriolis Composites and Victrex have each utilised their own specific technologies and know-how in teaming up to use an Automated Fibre Placement (AFP) process using parameters that unlock the potential of VICTREX AE ™ 250

LMPAEK UDT which could benefit engineers at the aerospace OEMs and in the tier and processor supply chain. Specifically, the cooperation on composite process development could enable the aerospace industry to create composite parts faster and more economically.

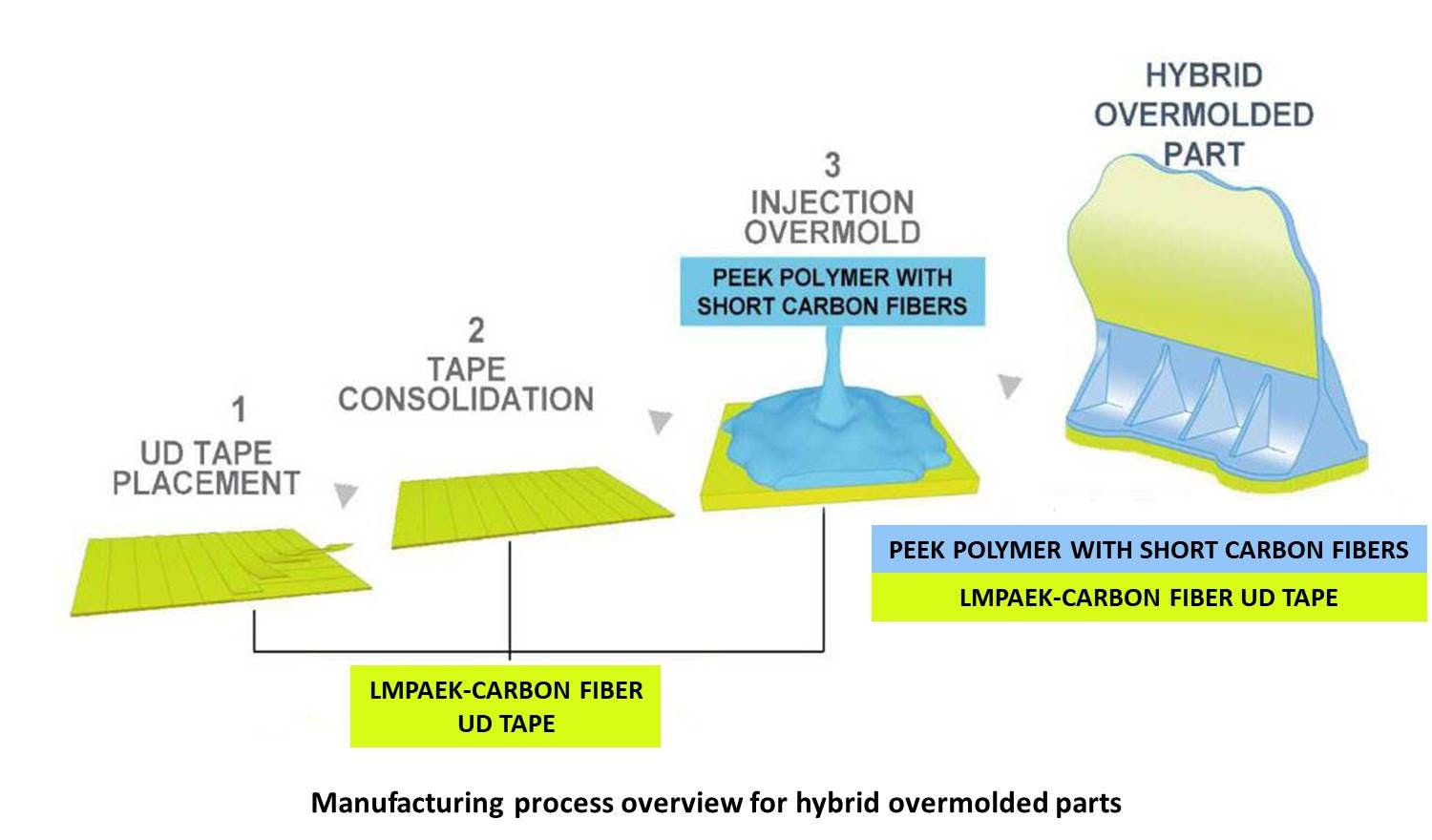

The results of the study are unprecedented in terms of lay down speed at acceptable porosity levels for TP UD laminates. This is a decisive step towards enabling the market to scale up manufacturing and realize the benefits of TP UD tapes. VICTREX AE 250 LMPAEK UDT holds the potential for manufacturers to exceed speed of manufacturing of an existing TP UDT intended for the same applications, and rivals Automated Fibre Placement/Automated Tape Laying (AFP/ATL) deposition rates for thermosets without the necessary lengthy autoclave consolidation time required for thermoset UDT (TS UDT).

“During the presentation, we will demonstrate how, with VICTREX AE 250 LMPAEK-based UDT prepreg tape, we have been able to achieve a faster lay-up speed when followed by Out of Autoclave (OoA) consolidation. The results of our study are a significant improvement over what we’ve seen for a similar TP UD tape,” summarised Dr. Stuart Green, Market Technology Manager for Aerospace at Victrex.

VICTREX AE 250 LMPAEK UDT: Highly efficient production for both in-situ and Out of Autoclave consolidation

Key to the cooperation is the joint offering of an optimised AFP process that delivers impressive time and energy saving benefits in both in-situ and ‘Out of Autoclave’ (OoA) consolidation as compared to another polyketone UD tape intended for similar applications.

“We developed a set of conditions that demonstrated time and energy savings, indicating the potential benefits of the deployment of AE 250 UDT composites for large scale structural aircraft parts,” said Dr Justin Merotte, Composites Project Engineer at Coriolis Composites. “In particular, the results showed that a significant increase in lay-up speed was possible with VICTREX AE 250 LMPAEK UDT whilst at the same time achieving the low levels of porosity desired for in-situ consolidation.”

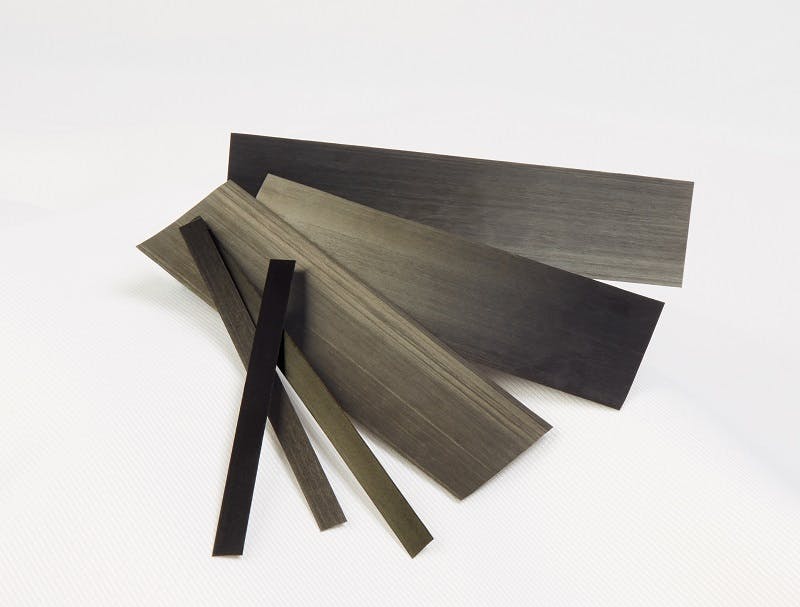

VICTREX AE 250 is a unique, high-performance thermoplastic composite prepreg tape that was designed by Victrex to have mechanical, physical and chemical resistance properties typical of the Polyaryletherketone (PAEK) polymer family, such as PEEK, but with a 40 °C lower crystalline melting temperature, at only 305°C.

The joint presentation will take place on Tuesday 12th March at JEC World Technical Conferences 2019 by Dr Stuart Green, Market Technology Manager for Aerospace at Victrex and Dr Justin Merotte, Composites Project Engineer at Coriolis Composites.

Further information on Coriolis Composites:

www.coriolis-composites.com

+++

About Coriolis Composites

A specialist in the implementation of composite materials Coriolis Composites develops, makes and markets robotic cells for fibre placement using a standard robot enabling the laying of continuous or discontinuous fibres, in all directions and on complex geometrical surfaces. Our objective is to develop and supply automated solutions for the manufacture of composite parts. The aim is to enhance mechanical performance thanks to low costs and an energy efficient, reliable technology that enables layup using a variety of composite materials. With its head office near Lorient (France), it has five other sites in Augsburg (Germany), Bristol (United Kingdom), Montreal (Canada), Shanghai (China) and Seattle (USA). There are also agents based in Russia, Turkey, Japan, South of Korea and Brazil. Coriolis employs more than 150 collaborators, 50% of which are expert engineers in many domains, from mechanical to software, through to composites and robotics. Please contact sales.support@coriolis-composites.com for more information.