A leader in PAEK based composite materials and solutions

More than ten times higher impact strength and damage tolerance compared to thermosets.

Consistent quality and tight tolerance contribute to predictable, tailorable performance including localised reinforcements.

Fatigue resistance and strength are comparable to metals with weight savings up to 60% lighter compared to metals and metal alloys.

Long-term reliability due to excellent fatigue and creep resistance.

Up to 50x greater fatigue resistance vs metals typically used in anatomic trauma plates.

Greater durability in harsh chemical environments compared to metals.

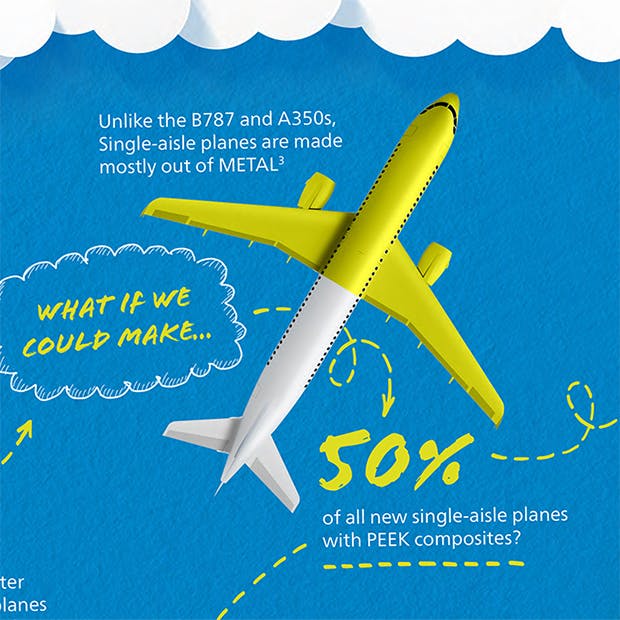

VICTREX LMPAEK™ composite material technology is being adopted in aerospace applications as metal and thermoset replacements due to the increased need for aerospace composite technologies to provide faster throughput, better performance, higher mechanical properties, and cost reductions.

Victrex has worked in partnership with Magma Global to develop PEEK composite capability, expertise, and solutions, which has enabled Magma to create m-pipe®, a reliable subsea pipe with greater durability, long-term reliability, and lighter weight for jumpers, risers, and flowlines.

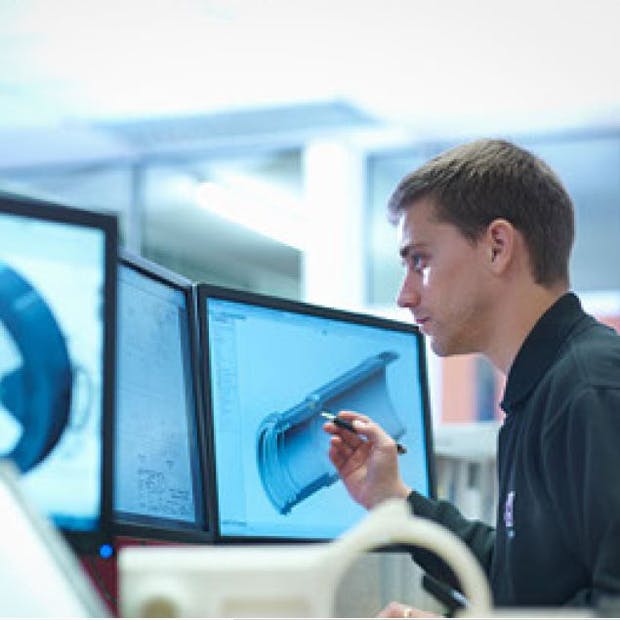

Victrex’s medical company, Invibio, is currently the only biomaterial solutions provider with the capabilities to commercialize PEEK-based trauma devices. Invibio works with its partners to overcome design and manufacturing challenges by offering comprehensive assistance, including design for manufacturing, prototyping, validation, and production services.

From the invention of PEEK over 40 years ago, Victrex has continually pioneered new PAEK-based polymers, materials and solutions that have transformed markets, delivering global impact in the toughest environments.

We bring transformational & sustainable solutions that address world material challenges every day.

Hi, do you have PEEK questions I can help with?