Boosting the performance in harsh environments

Boosting the performance in harsh environments

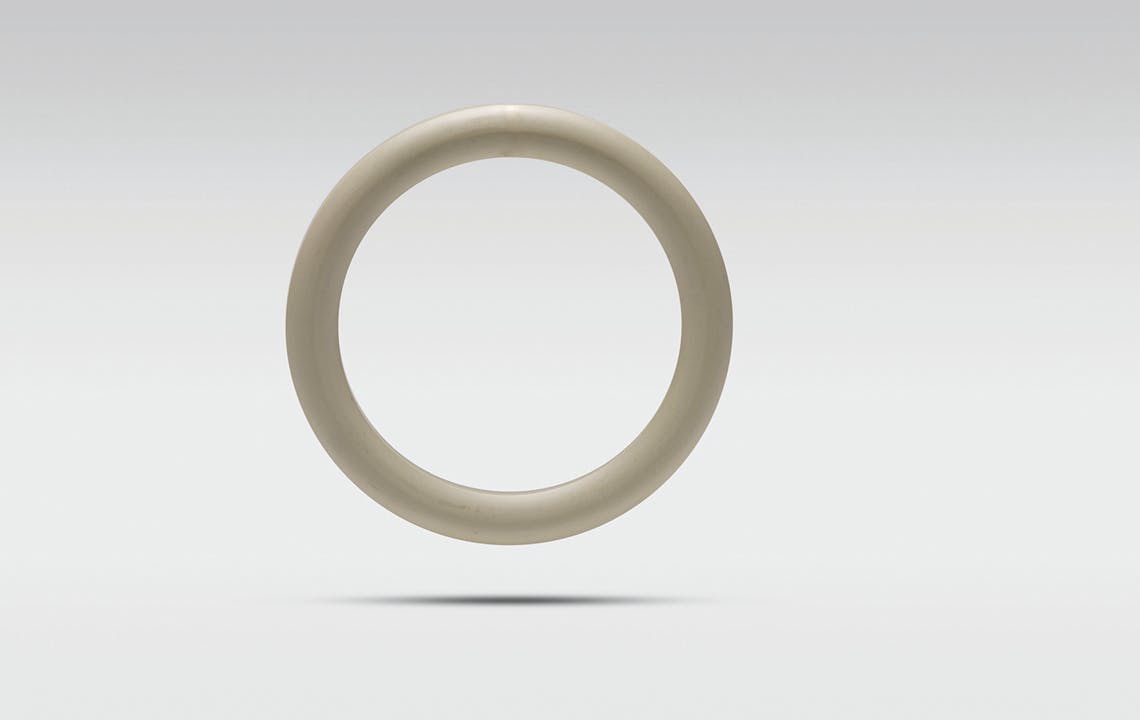

Effective sealing is often the difference between a safe, long-lasting, efficient operation and costly downtime. VICTREX™ PEEK has been a material of choice in this industry for 40+ years as a primary seal, back-up ring where reliability is critical. Proven 450G™ PEEK-based sealing solutions can extend the lifetime of installations and improving recovery in corrosive, HPHT environments .

VICTREX HT™ and VICTREX ST™ polymer materials are increasingly being selected by connector OEMs to improve application performance, achieve more design freedom, and reduce downtime and system costs.

Driven by stringent industry requirements for longer-life parts and reduce downtimes, VICTREX PEEK solutions delivers a unique combination of properties for compressor components.

As operating conditions become more extreme, with unparalleled electrical, mechanical chemical and humidity resistance properties, energy engineers are choosing APTIV thermoplastic film as a reliable technical solution for electrical insulation.

Traditionally, wear ring components have been made from metallic materials such as bronze, stainless steel and cast iron, but VICTREX PEEK polymer-based composite materials can be use as a metal replacement resulting in enhance process reliability, greater energy efficiency and a consequent cost saving.

Learn more about how Victrex is pushing boundaries towards future performance in oil and gas industry

From the invention of PEEK over 40 years ago, Victrex has continually pioneered new PAEK-based polymers, materials and solutions that have transformed markets, delivering global impact in the toughest environments.

We bring transformational & sustainable solutions that address world material challenges every day.

Hi, do you have PEEK questions I can help with?