Sustainable Materials: How PEEK polymers support ESG goals in Manufacturing & Engineering

The 2015 Paris Agreement set an international commitment to reduce global warming and accelerate the move away from fossil fuels. Growing legislation1 for decarbonisation has also brought about new standards by which to measure and manage emissions.

When we consider this impact on the automotive industry, the sector is going through significant change, with many in the supply chain looking to reduce their impact on the environment and assessing a wide range of aspects of their product offer and operations.

Car manufacturers have used various approaches to ensure vehicle compliance to legislation ranging from materials selection to car redesign to enable the manufacture of more sustainable vehicles with reduced weight, improved efficiency and thermal management.

Advancing Performance – Addressing Carbon Footprint

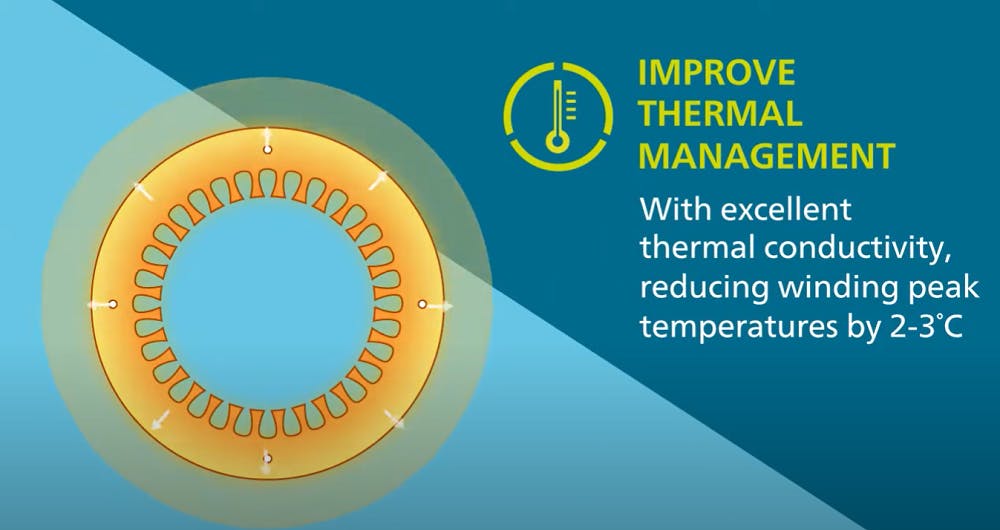

In terms of material selection this opens numerous opportunities for the use of PEEK polymer, regarded as one of the highest-performing polymers in the world. Looking at the fast-growing segment of high-voltage electric motors for example, the use of the electrically insulating and highly thermally conductive, thin PEEK-based APTIV™ film in e-motor slot liners can help to reduce overall motor size and weight at a given performance compared to traditional laminate insulation materials.

In high-performance 800V e-motor magnet wire production, VICTREX XPI™ PEEK polymer can provide benefits such as enhanced reliability with its very good electrical and thermal properties. The ductility of the material gives engineers the freedom to design more efficient cooling systems and makes it suitable for state-of-the-art winding technologies, e.g., wave winding which requires tight bending radii to achieve smaller winding heads.

60% energy savings in a solvent-free manufacturing process

From an environmental perspective then, using PEEK can save up to 60% energy using a 1-step extrusion versus traditional multi-step enamel coating processes2. VICTREX PEEK is solvent-free, which also eliminates the need for hazardous solvents typically associated with wire enamels – another aspect to consider in moving towards more sustainable electric machines.

As one of the highest-performing polymers in the world, PEEK also gets increasing attention in e-motor applications such as bus bars, rotor sleeves due to its thermal, electrical and mechanical properties and chemical resistance.

Whilst these are examples in electrified powertrains, there are many areas in transmission, engine, chassis and braking applications where VICTREX PEEK has been successfully used to minimise friction - which accounts for a significant share of energy losses in the powertrain – and considerably reduce component weight by up to 68% vs. metal parts. This way, around 80,000 tonnes of CO2 savings are being achieved from selected automotive applications made with our products every year3.

Additionally, Victrex is committed to environmental reporting through the Carbon Disclosure Programme and the GHG (Greenhouse Gas) Protocol and has set its strategic vision for carbon reduction for GHG Scopes 1 and 2 relating to emissions. The focus is on minimising use of resources in our operations and continuous improvement initiatives across our business processes. Since 2017, Victrex has reduced its carbon emissions by 30% and 88% of our R&D investment supports sustainable products. Currently, 97% of our products are manufactured using renewable electricity.

Our sustainability agenda has been recognised with a variety of leading accreditations including MSCI “A” Rating in 2022, an Ecovadis Gold rating in 2022, the inclusion in Apple’s clean energy supplier programme, and the 2022 Financial Times/Statista European “Climate leaders” ; recognition as one of only 400 companies.

So, at Victrex, our priority is clear. We will continue to drive for environmental improvement both in collaboration with our customers and to support a more sustainable future for the Automotive industry.

You can find out more about our e-motor solutions here. We’d love to hear from you about which challenges you’re facing on your path to sustainable mobility and discuss if PEEK can potentially accelerate your projects.

REFERENCES

1) Automotive Regulatory Guide – 2022 - ACEA

2) + 3) Data on file at Victrex