"We need to respond to many demands for aircraft brackets and similar structural parts, with each case having many loading, constraint and exposure conditions," said Tyler Smithson, Sr. R&T Engineer at Safran Cabin. "The key to success is to develop a flexible composite platform that can be used for multiple projects, lowering our part count and design complexity, cutting time-to-market, speeding time-to-revenue. Working with Victrex, we think that's what we've achieved!"

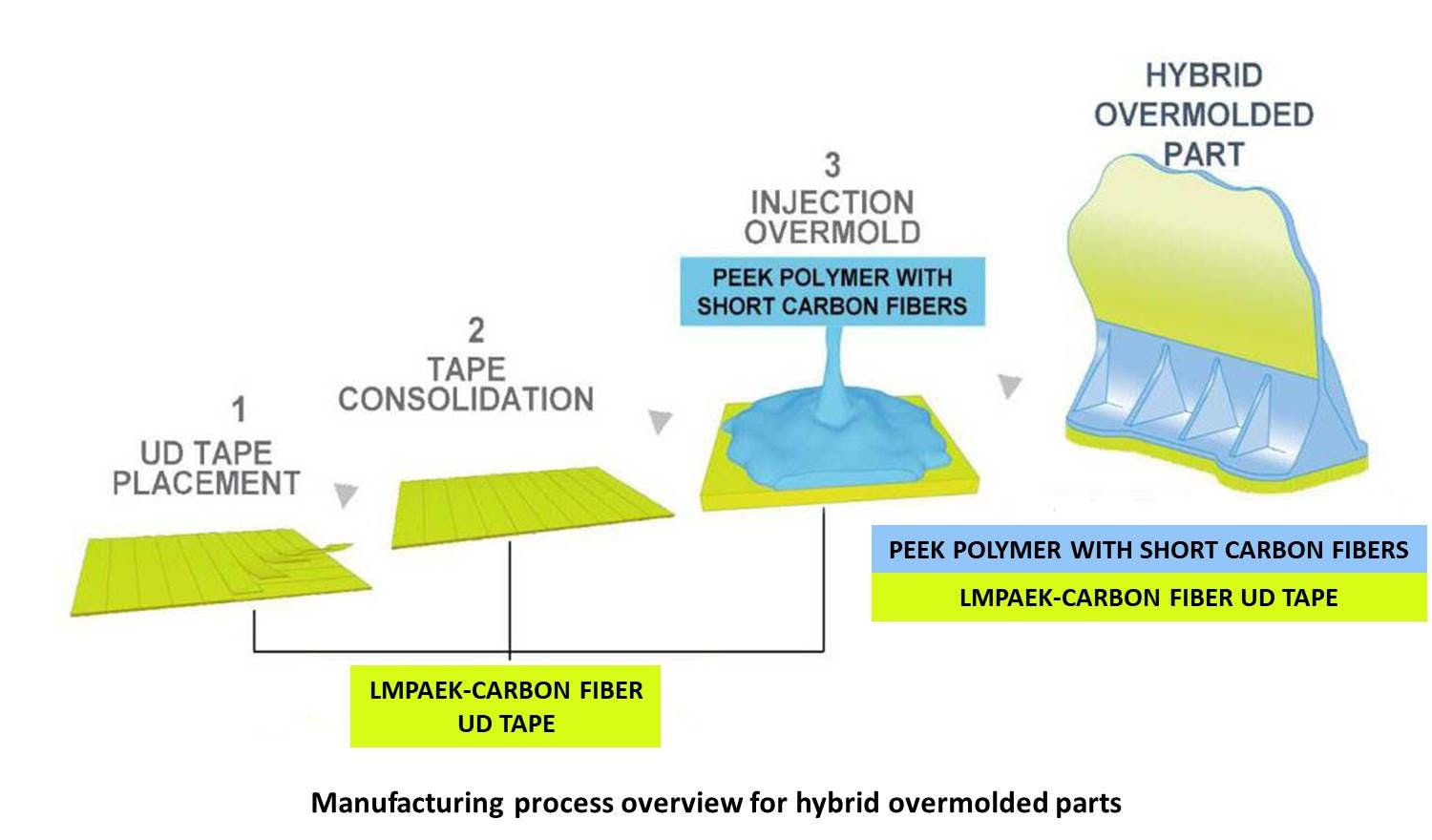

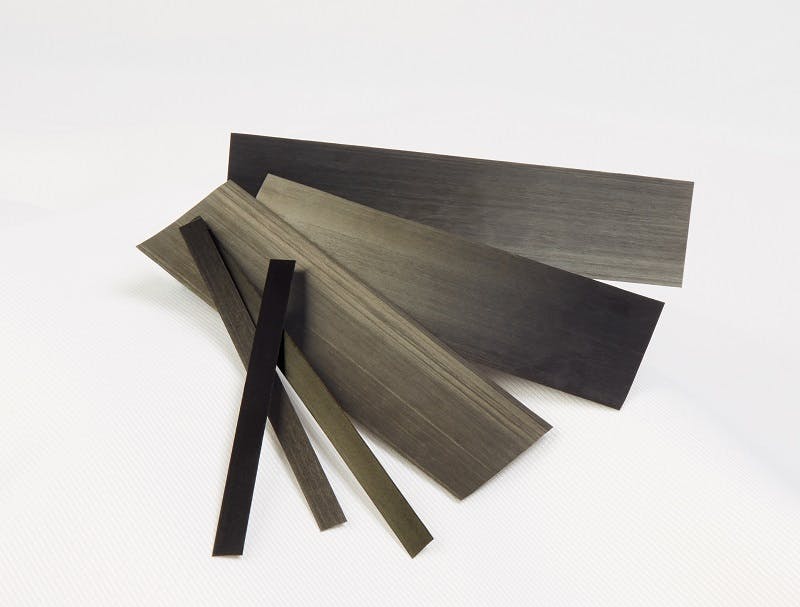

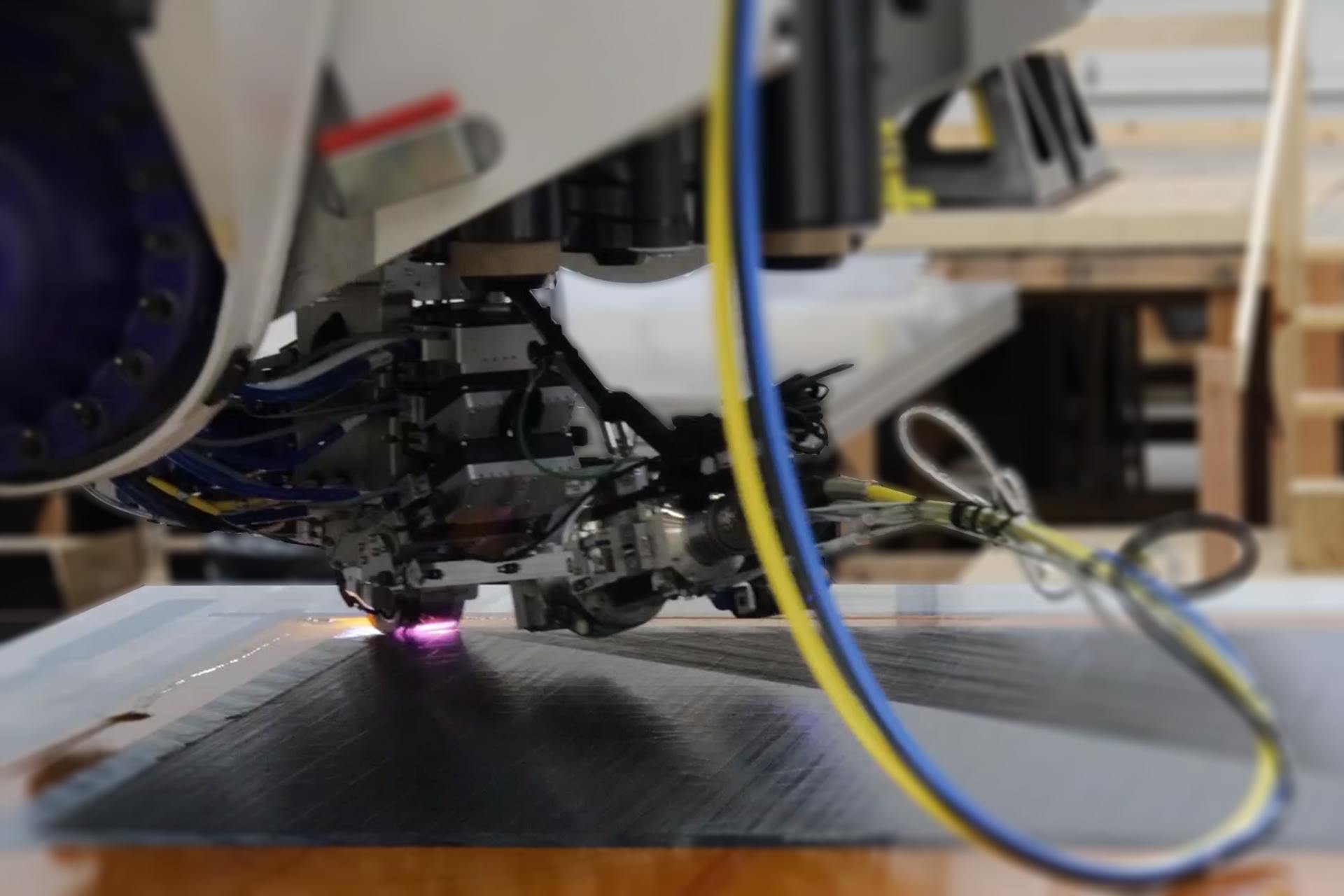

Victrex and Safran Cabin utilised an innovative technique where VICTREX AE™ 250

LMPAEK thermoplastic composite is overmoulded with VICTREX™ PEEK

high-performance polymer. This “hybrid overmoulding” technique is a scalable, repeatable technology with potential to help commercial aerospace customers face the challenges of needing much lower scrap rates, faster cycle times, part consolidation and reduction in the number of secondary operations. Stringent testing and qualification work have indicated that structural aircraft parts produced from VICTREX AE 250 LMPAEK via hybrid overmoulding can withstand high levels of mechanical stress.

Driving future aerospace design

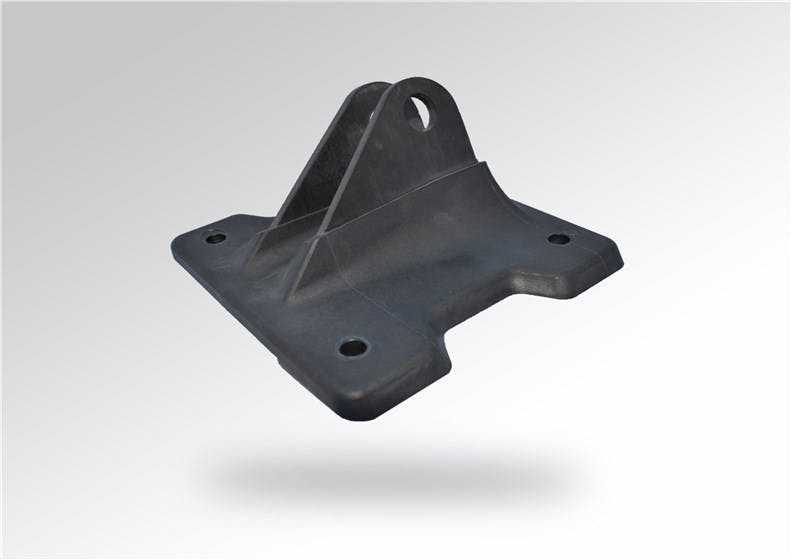

With Safran Cabin, the design process focused on defining parts and moulds adaptable for multiple brackets, with the goal of achieving a family of designs compatible with the same mould. This involved establishing a cost and weight advantage while considering the flexibility of the platform to be used in various applications.

Following the initial design phase, mould-filling and structural simulation methods were combined with various physical testing techniques to identify and mitigate new technology failure modes and to streamline injection moulding manufacturing and cost constraints. Critical characteristics were refined and a productive, repeatable design process has been developed.

"At Victrex we are proud of our track record in introducing 'disruptive' technological approaches in the sectors that we serve, using our know-how in the processing and performance of

PAEK materials to accelerate the commercialisation process." commented Tim Herr, Director Aerospace at Victrex. "Hybrid overmoulding and VICTREX AE 250 LMPAEK composites are certainly within this category but this is just the beginning. We continue to test our composites offering, with support from our customers and partners in order to demonstrate the full potential of these materials.”

Superior performance: brackets to be put to service later this year

The initial prototype brackets were produced at

Tri-Mack Plastics Manufacturing Corporation. Compared to the original aluminium part, the prototype composite resulted in have shown up to 20% cost savings; 50% weight savings; and a 5x better buy-to-fly ratio.

Currently the bracket is scheduled for final testing and qualification of production parts. The plan is to put the composite bracket in service later in 2019.

Tech Paper presentation at CAMX

Title

“Developing a Hybrid PAEK Overmoulded Thermoplastic Composite Bracket”

Time:

Tuesday, September 24, 2019, 2:30 PM - 2:55 PM, Anaheim Convention Center I 210D.

Location:

CAMX, the composites and advanced materials expo – Sep. 23-26, 2019, Anaheim, California/USA.

References

1) Polyaryletherketone or PAEK is the name of a family of high-performance thermoplastics such as Polyetheretherketones or PEEK.

About Safran Cabin

Safran Cabin is the world’s leading supplier of cabin interiors for regional, narrow and wide-body, business and military aircraft. The company's product range includes integrated cabin interiors, overhead bins, galleys, lavatories, crew rests and cargo containers.