How implantable electronic medical devices can help improve patient outcomes and lower treatment costs

The cost of poor medication adherence

Medication adherence among patients with chronic diseases averages only 50% in developed countries according to the World Health Organization (WHO). Non-adherence has significant ramifications, both clinically and economically. For patients, it can result in poor health, requiring additional hospitalizations and medical visits. It reduces productivity and compromises quality of life, possibly ending in death. It also significantly burdens healthcare systems, with estimates of avoidable costs ranging up to US$290 billion in the US and €1.25 billion in Europe. You can read more about this in the blog post "Drug delivery devices: How everyone wins when patient compliance is achieved".

Implantable devices: Smaller dimensions and miniaturisation

Implantable or wearable drug delivery devices such as insulin pumps, used in the treatment of diabetes, could make a major contribution to the improvement of medication adherence. The current trend for these devices is to become less invasive, with smaller dimensions and parts miniaturised to precise tolerances. This results in reduced weight and greater ease of use. When complex electronic components must be embedded, they too are designed to be compact, with a wall thickness that is as thin as possible.

The main objectives in developing a new device include:

- Positive impact on patients: therapeutic success, easy to use, treatment adherence

- Lower barriers to innovation: reduced costs, speedier time-to-market

Investigation into high performing materials can help to address these needs, as can partnering with an experienced material-solutions provider as early as possible during the design phase. Take a look at our blog post "3 key factors to consider for material selection in drug delivery devices" for more on this.

Implantable PEEK – a winning formula

After the first high-performing implantable PEEK (Polyetheretherketone) was introduced by Invibio in 1999, the company continued to pioneer novel materials, and PEEK gained more and more acceptance in the medical market.

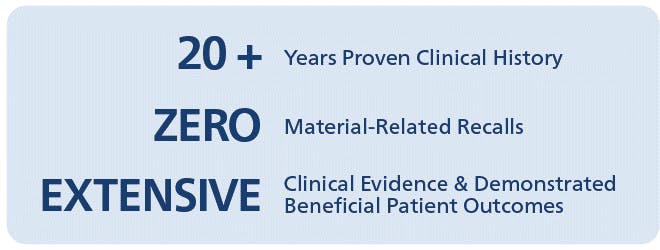

The medical industry has successfully utilised this unique polymer for long-term implantable devices – for spine, trauma, orthopedics, extremities, cranio-maxillofacial and dental applications. Invibio’s medical-grade PEEK-OPTIMA™ polymer is a reliable implantable material with 500+ medical devices FDA cleared in the US alone, and 13 million devices implanted worldwide:

There are many underlying reasons for the successful use of PEEK in medical devices. The thermoplastic polymer is biocompatible, which is an absolute requirement for implantable applications. Also, PEEK is inherently radiolucent, so medical imaging by X-ray, CT scan and MRI, are artefact-free and therefore facilitate monitoring and diagnosis with unobstructed views. It can be sterilised using standard processes such as gamma and e-beam radiation and steam sterilisation.

Advantages of PEEK for active implantable and electronic medical devices

Evolving minimally invasive surgical techniques require continual advancement in catheter and intrathecal systems — whether developing a catheter to be used acutely in the delivery of a specialized device or a drug delivery system that will be implanted long-term:

- A range of biomaterials with high tensile strength, tailored radiopacity and compatibility with multiple sterilization methods

- Easily extruded into tubing with excellent kink resistance

- Ability to be molded or machined for complex catheter connector components with high-strength and MRI-compatibility requirements

- Highly resistant to a wide range of chemicals

- Resistant to stress cracking - the process that can occur from extended exposure to liquids when used as a port

Are you about to design the next generation implantable, connected e-drug delivery device or interested in medical devices in general?

About the author

Marcus Jarman-Smith, Strategic Marketing and Business Development Manager at Victrex

Marcus joined Victrex in 2006 and has held technical roles with Victrex's medical business unit (Invibio) and commercial roles, most recently in Business Development, scouting for breakthrough technologies as well as supporting the development of Victrex's Additive Manufacturing offering. Marcus holds a PhD in chemical engineering, tissue engineering and biomaterials from the University of Bath, in the UK. Marcus's expertise is in PEEK in medical and dental applications as well as food contact, materials and technologies for Additive Manufacturing and 3D printing.

About the author